So, confession time: It is more difficult to keep up a weekly column than I originally thought it would be. When I took this on, I noticed that many of the weekly columns had burned out, and I decided to show these layabouts what a real weekly column looked like. None of this ‘three or four articles and then I’m done’ garbage. Firearms Friday would become a cornerstone of the Glibertarian community; A stalwart pillar representing the foundation of our proud website. Well, to those I privately disparaged, I apologize. It is not as easy to keep up a regular article as I anticipated, even one that has as much depth and variety as a gun themed screed. Nevertheless, I will persist with this as long as I can manage, which means you are stuck with me for the time being. This week, by popular demand, I will look into the business of making your own firearms yourself. Much hullabaloo has been raised and many gallons of digital ink spilled in reference to DIY guns, namely 3D printed guns and so called 80% receivers. Most of this ink has been accompanied by an equally copious amount of feces lining the panties of the writers of these various articles over the idea that anyone, ANYONE AT ALL, could build their own functional firearm in the comfort of their own home or garage with just a few simple tools or an inexpensive printer and a roll of plastic filament. Well, I am going start out up front with some bad news: you aren’t going to pop a working M60 out of your makerbot anytime soon, or probably ever.

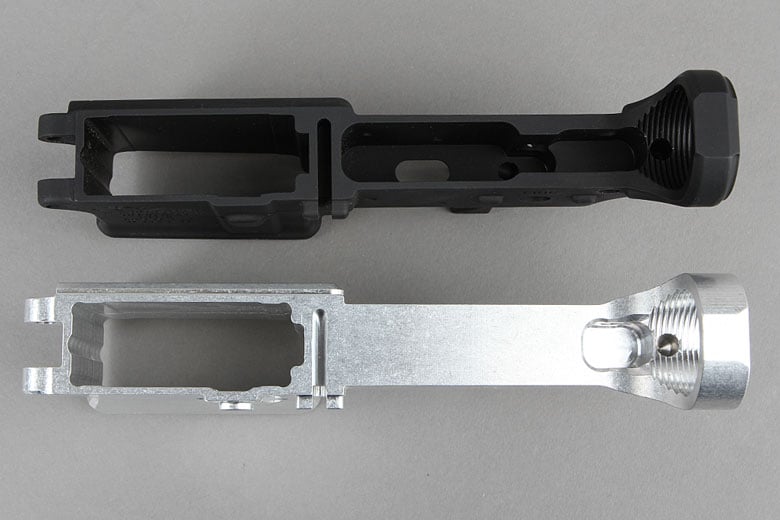

Complete lower on top, 80% lower on bottom.

Before I drop too many turds into this 3D printed punch bowl (so far this article has enough poop references to be a SugarFree piece) lets back up a bit and define some of these ideas more clearly. First off: What makes a gun a gun? Obviously it requires a specific quantity and type of parts as well as certain mechanical abilities, but at what point is it no longer just a pile of steel and wood? Legally, in America a gun is defined as the part designated as the frame or receiver. Every other part of the gun, including the barrel, trigger, stock, etc. is merely a part and can be bought and sold as freely as a toaster. The receiver, however, is always considered a firearm regardless of it’s functionality. It must be engraved with a unique serial number and is subject to all rules and regulations regarding working firearms. This means that you can buy all of the parts necessary to build a gun without any sort of paperwork or background check, except for the receiver which must be purchased either from a gun store (thus requiring a background check) or face to face from another resident of your home state (subject to local restrictions). At some point, some wise ass got to building a receiver, stopped before he drilled the last hole, and said “So this doesn’t count as a gun, right? LOL!” This pissed the ATF off, I’m sure, at which point they declared that almost a receiver IS a receiver, and then probably shot the guy’s dog. Well eventually people started asking questions about this ‘almost a receiver’ crap. Is a halfway finished receiver still a gun? How about a solid block of raw billet? The ATF realized they needed a concrete point at which a receiver was actually considered a firearm. They came out with a set of guidelines concerning what machining and manufacturing operations constituted a finished receiver, and guns meeting this definition were considered ‘finished’. You can take a piece of metal up to that point and it’s still just a piece of metal, but if you go one cunt hair over that line it is considered a receiver and you better have your papers in order. This is known as the 80% rule (considering most guns are black they probably should have called it the 4/5ths rule) and it is where the term ‘80% receiver’ comes from. By far the most common 80% receivers are for AR 15s, but you can also get them for AKs, 1911s, Glocks, and a whole slew of other guns.

An 80% lower in a jig. The jig is used as a guide for correct hole placement and pocket depth.

So what does this mean for you? Well, it means you can buy one of these 80% receivers, finish it at home using a mill and/or other tools, buy the rest of the parts online, and build yourself a working baby killing death machine without any kind of background check or paper trail. At least, that’s what some people with an above average supply of tinfoil say. I personally am not so sure (more on that later). Confession #2, I have absolutely no working experience with 80% lowers or 3D printed firearms. I do, however, have some experience with CNC milling and additive manufacturing (3D printing), so I am aware of what is involved and what each is capable of. There are 2 common materials used in 80% AR lowers: polymer and aluminum. Polymer is not as strong or as stiff but is much lighter and much easier to shape. Polymer80 is the most well known of polymer AR lowers, and they sell a kit which will let you make a polymer lower using a drill press and a dremel. They also make 80% Glock frames as well. The other option is aluminum. Aluminum is much stronger but also heavier and not as forgiving to machine. 80% Arms has a kit for finishing an aluminum lower using a routing tool commonly used for woodworking. If you already have one then this is probably your best bet, or you can pick one up for about $80. An aluminum lower is going to take much longer to complete than a polymer one, but the end result should be much better quality. The initial cost for these kits are relatively high, but once you have them you can purchase more 80% lowers for cheap and finish them up for essentially free.

Cody Wilson: American Hero

The big problem, however, is that these kits take a) time, b) a workspace, and c) a modicum of skill. Some people lack one or more of these items, making an 80% build problematic. Fortunately, there is a solution. For those of you on here who have not heard of Cody Wilson, shame on you. Turn your libertarian card in at the door, you just failed the purity test. Cody Wilson is basically the ancap equivalent of Che Guevara. At the age of 24, he founded a company called Defense Distributed. I am pretty sure he picked that name only because ‘Fuck the Police’ was already being used. His first order of business was to develop and release CAD models of a fully functional 3D printed handgun called the liberator, which I will discuss a little later. This caused such an uproar that the government forcibly took down and banned the files, citing ITAR infringement. He is currently suing the state department over the matter. Not one to rest on his laurels, he started his next big project, called the ghost gunner. The name comes from the term ‘ghost gun’, which California state senator Kevin De Leon made famous in a hilariously incoherent cringe inducing speech he made on the subject. The ghost gunner is a purpose built CNC mill specifically designed to machine AR lowers. Simply drop in an 80% lower of your choice, push a few buttons, and in about 2 hours a finished, working AR lower pops out. For a mere $1500, you too can crank out as many unregistered, untraceable AR lowers as your little heart desires. If $1500 seems a bit steep, I can assure you it is a pittance compared to what a traditional CNC mill will run, and the added software which makes finishing lowers as easy as running your microwave is a nice bonus.

Kevin De Leon: Pants on head retarded.

I can already hear some of (((you))) now “$1500?! I can’t afford that! Isn’t there a cheaper way of doing it?” I’m glad you asked. For those of you that can’t afford the wonderful ghost gunner mentioned above, there is a slightly more economical option. With a suitable 3D printer and good quality polymer, you can, in fact, print an AR lower. There are working examples on the internet, and a decent 3D printer runs in the $200-$500 range. Now, don’t think it’s going to be as simple as pushing a button, or that you will get a working lower on your first try. I know from my experience with 3D printing that it is usually a trial and error process, and that it takes a very long time to print anything. Don’t expect to it to look great or be terribly durable either. I expect no more than a few thousand rounds out of a printed lower, tops. It does work however, and if you break it you can always print another one.

This is a working metal 3D printed gun. It costs about $12,000 each. And yes, they named it ‘Reason’.

But there is a flaw with all of this. Ostensibly the point of making your own gun is to keep da gubmint from knowing about your ballistic proclivities. But does making an AR lower yourself actually do that? Technically Uncle Sugar is forbidden from maintaining a database of firearms purchases. I highly doubt anyone here actually believes that they do not, myself included. If we concede that the government is willing to break its own explicit laws to keep track of gun owners, however, then our logic eats itself. Remember that these lowers are not functional firearms themselves. You still have to buy quite a few components and assemble them. Unless you pay cash (or bitcoin) for every part of your gun and all of your ammo, then you’re already on the list. What about 3D printing, you ask. What about it? The only working gun that I am familiar with that can be 100% printed is the liberator, which is a single shot 380 pistol with no rifling. Half the time these explode when they are fired…. not exactly military grade. There are metal 3D printers, but they are hundreds of thousands of dollars and you can’t simply order one off of Amazon. In short, 3D printing is simply not a viable strategy for building a working gun, at least at the moment.

So, if you’re doing this to try to stay below the radar, then you’re probably better off simply buying a gun off of armslist from a private seller. If, however, you’re doing it cause you’re worried about a gun ban at some point down the road and you want your instruments of insurrection… well, you’re still boned, because I really doubt you’re going to be able to run down to Cabelas and pick up a lower parts kit and a barreled upper, no matter how many lowers you crank out. If you’re just doing it for funsies and to put a middle finger to the law, then have at it, my devious little anarchists! There is way too much ground to cover on this one topic in just a short article like this, so I highly recommend you do your own research if you’re interested in making your own guns.

The future is steel…. and about 4 inches long.

Before I go, there is one upcoming product that I do want to mention, because I believe it is going to have a serious impact on the future of 80% firearms. Most of you are familiar with the Sig P320, but for those that are not, it is a striker fired handgun that was recently selected as the new issue sidearm for the US army, and probably all of the military will be issuing it in a few years. What makes the P320 unique is that the registered part of the gun, the part that makes it a gun, is not the frame. The P320 is built on a removable stamped steel chassis that allows you to change out grips and slides quickly and easily with no tools. You can switch out a broken frame for a new one in the field, or simply change your full sized pistol into a compact or subcompact one in a few minutes. A company called Ghost Guns (notice a pattern?) recently announced that they are releasing an 80% receiver for the P320. This has vast implications for a multitude of reasons. First off, the receiver of a P320 is remarkably simple. From looking at the videos released by ghost guns, a person should be able to finish a P320 80% lower with nothing more than a file and a hand drill, something most people already have and almost anyone can afford. Secondly, because the fire control group is removable as a single unit, that means that there is nothing limiting the chassis from being used in other guns. Imagine if a company released a rifle body that took AR magazines and used the P320 chassis as the trigger. Someone could buy one of these 80% kits, make themselves a P320 chassis, then install it into this rifle and have a working fighting gun, without ever doing a background check or even leaving the house. That is just one possibility for this system. I believe that we could be seeing the beginning of a whole new future for firearms development, and it is quite an exciting prospect.

This is known as the 80% rule (considering most guns are black they probably should have called it the 4/5ths rule)

The best thing I read the whole day.

I feel old. All of the guns I have and like are damned near antiques. I just dont like the newer designs. I probably have five times as many revolvers as autos.

If what you said is true then you ARE old. Still using dinosaur fat to lube up your flintlock there grandpa?

I cast all of my own bullets and use beeswax/paraffin for lube so….I guess the answer is yes.

*God, I love the smell those bullets make when they leave the barrel. It is my second favorite smell in the world.

Bullet lube recipe: Wax ring for a toilet (100% beeswax) and crayons. Mix 50/50 and melt. You can make a shit-ton of lube like that for just a few bucks and it works great.

I’m surprised that no-one here has yet asked whether it comes in 55-gallon drums on Amazon.

For a black powder pistol? Interesting recipe there.

Uh no, for all of my guns. I have been building a collection of molds since the ’70s. Want a particular bullet style? I have one.

A real patriot melts down their children’s toy soldiers to make musket balls like Mel Gibson did in that movie.

I use wheel weights. *sad trombone*

They used to be a lot easier to come by. I am down to about 500lbs

I will have to come up with another source soon.

My wife used a mixture of paraffin and a toilet ring to weather-proof her riding duster. Works a charm but I warned her to keep well away from open flames.

I only use royal jelly.

/hipster handloader

I have a Glock 17 made from an 80% lower, does that count?

Made it myself, and it actually didn’t require any real tools, just files, a drill, and a dremel tool.

How clean did it come out? How long did it take?

I did it over a few days, but all-in, including assembling the parts and everything, i’d say 4 hours or so, maybe less. Came out pretty clean, I think. couple machining marks on the inside that you don’t see, but that’s all. It’s run pretty flawlessly through almost 1k rounds, at this point.

What lower did you use? Is it a polymer80?

See you should have written this weeks article. You know more than I do about it.

Haha, well I’d definitely be happy to help out sometime.

Yes, it was the Polymer 80, first generation. They’ve made some updates for gen 2, as I understand it. Used all Glock factory parts for the rest.

Really the only problem I’ve had with the whole project is the cost. In the end, it cost more than buying one new, mostly because the existence of these 80% lowers has driven the price of parts up a lot.

This is what I’ve heard. You really don’t save any money unless you make a bunch of them.

Same here, without the Dremel. Turned out pretty well, if I do say so myself.

Nice, did you finish it out to a 9mm too? I was considering going .40 for a while because the Glock 22 slides were cheaper, but ended up going for the 17.

Hey buddy, what’s with the avatar?

BENDER FIGHT!!

It’s gonna be like battlebots up in here.

I was here first. He’s gotta go home and change into something else.

FNG can just change his avatar to alternate universe Bender.

https://m.youtube.com/watch?v=95ob-RacmhM

Can I print a reasonable facsimile of a NYS gun license too?

No, but I know a guy…

Sure. Self finished licenses look like this

https://goo.gl/images/ALXnNx

The P320 chassis is intriging. Plus apex makes a trigger shoe for it…I just don’t trust the ATF to not to suddenly change the rules to the game.

I recall an engineering student on M4.com making a bullpup system using an AR lower as a drop in. Same line of thinking.

During my research for this piece I found a 3D printed bullpup lower but it requires an upper that works without the buffer tube, and there aren’t many of those.

I see. I remember the guy getting banned because he was tying to ping the forum for ideas and half the assholes there kept insisting he was violating the forum’s rule against sales pitches.

Its definetely a fun idea though with the aftermarket for Glocks and 1911s, you can build a truly bespoke piece out of an 80% and assemble the rest with custom parts.

Cool article Vhyrus. I appreciate your efforts.

It is not as easy to keep up a regular article as I anticipated, even one that has as much depth and variety as a gun themed screed.

Yep, agreed. When you’re a part-timer, life catches up with you and you can’t devote the time required to put out quality content. I put out a few “iffy” articles before putting it completely on hold. Having an infant puts the kibosh on my writing for pleasure. Hopefully we have enough interested content generators here to sustain the momentum of this site.

Good on you for putting out sustained quality content! I always appreciate reading your stuff!

That’s no shit. It does take a lot of effort. I appreciate all of the contributions.

I thoroughly enjoy the Firearm Fridays, thanks Vhyrus! I am not a gun owner, but the influx of well presented info is much appreciated. You’re in AZ somewhere, so I’ll buy you a beer if you find yourself in/around central Phoenix.

I live in Mesa, so you may actually have to honor your offer 😛

I knew you were in AZ, so yeah of course the offer will be honored!

As a Canadian who mostly only gets to think about owning firearms, I too appreciate these articles. It’s nice to read stuff that doesn’t start with right-thinking Laurentian elite “no-true-Canadian” hoplophobic pants-shitting and then go downhill from there.

The P320 is in fact available at my local gun shop, although all variants of it are listed as “Out Of Stock” at the moment. I’m surprised that a “system” side-arm like this hasn’t already been banned by the RCMP due to the possibilities for customization etc. you mention in your article. The Mounties hates ’em some customizable weapons in the hands of mere non-law-enforcement citizens . . .

Look on the bright side: You guys get short barreled shotguns, and you had the Tavor like 5 years before we did.

Nothing shorter than 18 inches, though. NOTHING.

We can’t get anything shorter than 26 inches without going through an assraping. The only place we really have you beat is on magazine capacity.

I just realised you meant pistols too…. oopths.

Don’t be silly — we have plenty of pistols/sidearms available, just none with barrels shorter than 100mm (approx. 4 inches). Our cops freak about concealability, but all of our crims have all manner of weapons that violate one or more of the myriad rules regarding firearms in Canada. Like all other Right-Thinking Canadians, our police just don’t get that the rules don’t matter to non-law-abiding citizens, so everybody has to have the rules imposed on them.

True as far as I know, although to my surprise, I’m able to buy an un-modified Kel-Tec KSG with the 12+1 capability here without problem (other than its price and the fact that the KSG is kinda getting a rep for shitting the bed).

Also… there’s nothing stopping from.. oh I don’t know… coming down here for a few days… buying a few of these 80% lowers as souveniers… and then just… you know… finishing them at home…. I’m sure there’s a place in your yard you could bury a medium sized tupperware container full of…. things…..

Yeah, the CBSA (Canada Border Service Agency) is too smart for that. I had a CBSA agent as my instructor for the classes to get the PAL and PAL-restricted, and those guys knew the laws concerning firearms better than the cops did. 80% receivers would never make it across the border, and I’d have some ‘splainin’ to do . . .

Would they actually search you though? I don’t even get searched when I go to Canada.

They’ve got the border-crossing equivalent of “gaydar.” They seem to know when you’re bringing back microscopic particles of anything that’s verboten. It’s weird.

That is exactly right. They train for that. They can spot the average amateur smuggler a mile away.

Or he could just stay. My standard speech to Canadians on this site: “Get your ass across the border”

I get that from my BIL all the time. He lives in Seattle.

No thanks.

In all fairness, Seattle isn’t ACTUALLY America.

I know. It’s kinda the worst of all possible North American destinations.

I wouldn’t go that far. I mean, it’s not New Jersey at least.

Seattle? Fuck Seattle.

America is full of medium to small sized cities populated by mostly rural people who have their feet on the ground and their head screwed on right in states like mine (Louisiana) were you can walk into a gunstore at your leisure, have the clerk call the sheriff for a background check which is done in 5 minutes and then you walk out of the store with the gun of your choice. No classes, no registration, no asking anyone’s permission. You can be breaking it in in your back yard an hour later.

I’d rather kill myself than willingly go back to Minnesota.

Great articles….so, asking for some advice. I’m heading down to Colonial Shooting Academy Richmond tomorrow for a little outing. Confession – I haven’t fired anything since I last qualified on my Navy 9mm 3 years ago before I left my second ship (shore duty didn’t require any qualification/carry/etc – and Navy Reserve doesn’t require anything unless you’re full time support or getting ready to deploy).

My mid-term goal is an AR-type rifle, 12 GA, and a pistol….for the moment, I’m just going to test out a range of rental .45s. I haven’t fired one of those in even longer. Just want to blow through a few hundred rounds and get a feel for some different types again after so long. No plans to buy tomorrow…..although I’m considering the used Sig P220 they have listed – but since it’s not listed as a rental option, I’m not sure I’ll buy without trying. I may ask about it though.

Compared to say…motorcycle helmets….is there generally a downside to buying used? Especially with a high quality (recommended to me by a number of gun nuts at my last job) store?

The nice thing about guns is that they last forever. Unless it is in really bad shape (rust, non functional, bent/broken parts) used is a great way to go. If it is a common gun like a Glock, 1911, AR, etc, even if it is broken you can usually fix it yourself.

A buddy of mine bought a Sig P226 police trade-in for $350. It doesn’t look like it just came out of the box, but it’s in fine shape and was obviously well-maintained. When you consider how much a new Sig goes for, it’s worth the risk.

Looking for range and home defense or do you plan to conceal carry the pistol?

I have my eye on a Beretta Storm when I get all the appropriate NJ permission slips.

So… the 5th of never?

I like the PX4 Storm a lot. We can’t get most of the variants here (.40cal, no; any barrel shorter than 100mm, no), but it’s actually the sidearm of choice for the CBSA. Another “system” side-arm I’m surprised the RCMP hasn’t already forbidden us proles to own.

Home defense/general use initially. I can’t take their Concealed Carry training/range practice course (drawing/shooting/etc) without bringing my own gun anyways – so probably within a couple months.

Granted I live within a few blocks of where I work (and I can’t even leave my gun in my car where I work – secured military property) – but any other time after that…sure – VA is great with that.

Just spend like a week watching hickok45 videos.

The trouble with that is the old guy loves ’em all. I’ve yet to see Hickock45 say “Oh, this was a fun gun to shoot, but I wouldn’t own one”.

After you shoot, go to Mekong right next door. Vietnamese food with a great beer selection.

“there generally a downside to buying used”

A shit ton of people buy a gun, shoot less than 500 rounds through it, and then sell it. That’s basically a brand new gun. You just want to field strip it and function check. Especially if he’s got the box/manual/receipt, if it’s less than a year old, you got one of those people that buy the latest tacticool wunderwaffen, don’t fucking shoot it, but think they’re a badass.

I saw the listings (and another Brewpub next door – they might have changed the name), but since I’m driving right back to C’ville afterwards – I’ll just stop at Maggianos and use a GC from last Christmas.

The ANswer is the Brewpub owned by An, the guy who owns Mekong. Haven’t been in there yet.

Used guns can be great deals. Especially police turn ins. Those tend to be carried a lot, and shot a little with great price tags. I’ve purchased a lot of those and never regretted any of them.

Used is fine LT. I mostly buy used these days because the stuff I like has to be special ordered new. I have nevr had a problem and have good quality stuff. With some rifles you may find a bore that has been shot out but with pistols they never wear out.

Appreciate the feedback. I may be able to at least get a couple mags through it if I tell them I’m seriously considering it.

http://www.thefirearmblog.com/blog/2017/06/23/canadian-confirmed-kill-record/

Bullet was in the air for 10 seconds

That’s JTF2. Badass.

Commie Prime got his panties in a wad over it.

To be fair, JTF2’s history of being used in a legal and constitutional way is…messy. There’s been a couple of scenarios where Parliament finds out they were being used somewhere for something and the Armed Forces response is “lol we were going to tell you guys eventually. Seriously.”

Of course I trust the CAF a hell of a lot more than I trust Ottawa…

BWAHAHAHAHAHAHAHAHAHAHAHA!!!

To be fair to the commie, he has a point.

I mean, i’m continually pissed off that we pretend we’re not at war, but still have troops on the ground in 3+ countries at the moment. and have taken casualties in all of them this year. I’m not as non-interventionist as others, but i am at least committed to the idea that if we’re going to stick our dicks in other people’s fights, we need to be honest about what we’re doing and why.

Instead, we leak away billions paying for all sorts of dumb shit like refueling bombers attacking Yemen, Arming Syrian rebels, redesigning the fucking Afghan army’s uniforms, helping the psycho Filipino dictator fight his own insurgency… and yet nowhere do we ever really see any argument by a single politician about “why” we’re all paying for this shit, or why Americans are risking their lives to win other people’s wars.

Those Canadians really like to stay far away.

That is amazing shooting. The extreme long-range guys are really pushing the envelope these days.

If I were a Canadian sniper, I would have “Sorry!” engraved on a bunch of empty cases, and I’d leave one in every hide site where I took a shot.

You really want me shitting all over your weekly posts don’t you boy?

I can’t help it if our media library is big.

Looking at his body language I am thinking that guy is going to be standing there a long time.

I have actually seen porns based on this idea.

Yes, but have you actually seen porn based on this?

Goddammit Heroic, I really could have gone my whole life without seeing that.

Me too.

*thousand yard stare*

So in Japan, it is a widely held belief that twins are actually reincarnated lovers from a past life… which is why you see so much of this shit in Japan.

If I ever find who translated this, though, I am going to kick them in the nuts.

. . . I am going to kick them in the nuts.

Hopefully three ways: hard, fast and continuously.

That explains a lot.

Mostly why it was correct to show them no quarter on Iwo Jima.

Dammit where’s my disgusting Iwo Jima hentai already?

I am not sure the “in the womb” label was needed.

MANGA SHITPOSTING TIME.

As often as I click on that image eventually it’s going to come up in a HR meeting.

Rape Horse is love, Rape Horse is life.

Here’s a woman trying to masturbate with a broadsword.

Somehow watching the Berserk anime makes these MORE offensive.

At least turn the thing around.

That anime is a disgrace to the glorious filth that is Berserk, they can’t even animate a Rape Horse properly.

(the 90s one made by the people who made Pokemon’s pretty good though)

Oh, that chick also masturbates to setting people on fire and treats torture like her personal BDSM fantasies.

Farnese has fucking issues man.

So what’s you’re saying is that she totally deserved the horse rape.

Deserve’s got nothing to do with it.

I haven’t. Fortunately my girlfriend watches them and then describes them in great detail to me.

This is translation so unfair. The original Japanese hints at a more romantic relationship.

You know you’ve gone local when “you’re misrepresenting their rich narrative about twin fucking” comes up.

Maybe Straff is a twin. One never knows. NTTIAWWT

Hell, even they say they all look alike. It was a logical progression.

Wait, what the fuck was that

I’m pretty sure that was prenatal gay twin sex, Gilmore.

Oh, ok fine, nevermind.

My grandfather told me this about getting what you want when I was young: “Its like the guy who stands on the street and asks every woman that passes ‘Hey, wanna fuck?’. He gets slapped a lot but sooner or later one is going to say yes.”

King of the Hill episode.

Really? Huh.

I once heard a joke from an ancient relative. Chickens are fucking in the yard, rooster going from one to the other hen. Wife asks husband why he cant go that many times. Husband answers he could if he had more than one hen.

He told it as if it happened to him. Later I found out it’s an old joke that goes back so far it is lost int he mists of time.

Probably same is true for the man standing on the street.

Not quite, “Wanna fuck?”, but pretty close.

I don’t understand how this situation is possible given the existence of prostitution. Other than strict adherence to religious dogma.

Appreciate the effort Vhyrus. I am not the biggest gun nut, but appreciate the info.

I’m actually surprised no one commented on the ‘Reason’ handgun.

TSTSNBN1911

DRINK!

That reminds me — the temp’s rising outside, the Japanese porn’s freakin’ me out, my Patellofemoral Syndrome’s pissing me off and I’ve got cold Negra Modelo in the fridge.

Gonna get a beer. And some ibuprofen. Dammit.

SLS printing of steel will hit the desktop market faster than we think.

If it happens within 20 years I will be truly shocked. Right now it is unimaginably expensive and technical.

You need a sealed chamber with inert gas, a way to level each layer of powdered metal, a moderately powered laser, and a way to aim it.

I think patents is the main thing that has held back that revolution. Didn’t some of them expire a few years ago m

Nanotech makers?

If you’re interested, Here’s and interview of Cody Wilson given by Tom Woods. IIRC, he was probably the most cryptic guest I’ve ever heard on Tom’s show. Obviously a couple standard deviations above me, but very interesting guy.

Cody Wilson is the most fascinating and unapologetic person in an interview. He says some wild ass shit.

I got the vibe he sees himself as a kind of Übermensch. Then again, if your goal is to allow the Untermensch to arm themselves, I can live with it. Nice article BTW. My dad was always in the garage either working on one of his cars or making firearms when I was a kid. I loved working on the cars with him and we rebuilt 5 or 6 VWs over the years, but I never shared his enthusiasm for weapons. Did have my own 12 gauge and 22, but outside of small game and deer hunting, I never thought much about them. Wish I could go back and pick his brain, especially his knowledge of black powder.

Read his book. I think it would be interesting to non-gunnuts as well.

Elizabeth Warren is on the warpath against misogynist Republicans who want to defund Planned Parenthood

““I am sick of coming down to the Senate floor to explain to Republicans what Planned Parenthood does,” she said in an impassioned speech from the Senate floor Wednesday. “I am sick of explaining it provides millions of women with birth control, cancer screenings, and STI tests every year. I am sick of pointing out again and again that federal dollars do not fund abortion services at Planned Parenthood or anywhere else.””

But wait…

“Earlier this year, Planned Parenthood leaders refused an offer to receive an increase in taxpayer funding if they stopped doing abortions. CEO Cecile Richards called the offer “obscene and insulting,” making it very clear that abortions – not women’s health care – are what really are important to Planned Parenthood.”

In addition to being a eugenics operation they are a money laundering operation. They give money to Dem candidates. Thats why the dems freak out when this comes up. I am sure they dont use any tax dollars for that…or so I have been assured.

Defund. Them.

Money is fungible. But then, you knew that already.

Yeah…I was joking. But I have had that argument before and heard it from PP. We keep our tax money separate, we dont use it for XYZ. It’s enough to make you want to punch someone.

Meh, there are parts of the country where PP is the only low cost womyn’s clinic around. Sure, on principle, the government has no business giving them tax payer money, but in the larger scheme of things, it’s not all that important to me

I’ve read mixed reports on those numbers.

$700,000 is quite a lot of money to be wasting. Pricks.

Awesome article Vhyrus, thank you for writing it!

Anybody know who this guy is? I want to invite him to Evergreen as a guest speaker.

If I could get a boner from something political it would be that. That man is awesome.

Suppose I could’ve done an ounce of research myself. Here’s his Wiki page.

I dont remember who asked if muslims and libertarians could live together but I think I said in practice no, but in principle yes. Some select individuals. There is one right there.

That’s a remarkable interview, if its actually being translated accurately.

The interviewer actually inadvertently proves the guy’s point because he can’t seem to grasp what exactly “independent thinking” means.

“Should he be rebellious, you mean”? – as though the issue is always either complete submission to the collective will, or total antipathy to the public will; never a situation in which the individual isn’t even the slightest bit concerned with it, and simply goes about his/her own business without regard

He then says, “so you want us to be like Israel?”; which is again this kind of false-dichotomy thinking…. that the arab world either is perfect the way it is, or “The Enemy” (Israel) is the correct one.

Its fascinating to see at least one guy trying to argue that the arab world are prisoners of their own civilization

I wondered about the translation myself, but if you look at his Wiki page, you’ll see it sounds about right for the guy. “Listen, if you hate the West so much, just copy the Japanese who are copying the West”. Brilliant.

So has he already been blown up? and what’s the over/under on how soon he’s going to be blown-up?

I looked him up. Shockingly he is still very much alive.

I maintain that the Muslim reformation everyone has argued is necessary is ongoing.

The Christian reformation took 130 years, and was bloody and awful–comprising not just doctrinal arguments but political ones, too.

Started with Martin Luther’s 95 theses in 1517 and ended with the Peace of Westphalia in 1648–the last bit being the root of our First Amendment protections for religious freedom. Hopefully, the Muslim reformation will end up in the same place: The Peace of Westphalia and the First Amendment have held because they work.

Not sure where I’d date the beginning of the Muslim reformation. Much like the Protestant reformation, a lot of it is about struggling with modernity. Otherwise, I’d want to tie the beginning to the collapse of the Ottoman Empire–Ataturk tried to impose modernity from above, but that isn’t really what this is about. This is about masses of people–not the biographies of their rulers.

I think we should probably look to the Iranian revolution in 1979 as the beginning of the Muslim reformation–things changed after that.

…..or maybe it’s regressing from 1979 onwards.

Take her to Olive Garden.

Many people cite 1979 as the watershed year in Islamic Revivalism… not “reformation”; it was the point at which the forces for ‘re-islamification’ of their political society tipped firmly in a more conservative, fundamentalist direction

it was the year jihadis tried to take over the grand mosque, when the iranian revolution happened, and shortly thereafter the war of the Muj against the soviets took place.

https://en.wikipedia.org/wiki/Islamic_revival#Contemporary_revivalism

The Calvinists thought of themselves as a revival, as well.

Reading descriptions of life in Geneva under the Calvinists, you might think you were reading about ISIS or the Taliban.

My first girlfriend and her family were evacuated from Iran in 1979 with nothing but the clothes on their collective backs. She was a sweet girl and I’ve nurtured an abiding hate for everything tainted by Islam since then.

there’s literally no evidence anywhere of any “reform” movement in islam, currently. you have fundamentalists, and people mostly abandoning ship for the west. there’s no internal attempt at systemic change at all.

Not surprising. It’s a whack to the neck if it goes to a formal execution and a garden variety stoning if it doesn’t, for would be reformers.

ISIS and Al Qaeda can be seen that way. So can the Muslim Brotherhood.

These movements can be seen as trying to reform Islam and bring it back to its perfect roots.

Meanwhile, ISIS and Al Qaeda both have no legitimacy within the schools of of Muslim jurisprudence, and they’ve both had fatwas issued against them–if I’m not mistaken–by all four schools of traditional Sunni jurisprudence.

When ISIS and/or Al Qaeda issue a fatwa, they have no authority to do so . . . but they have to do it themselves because no one with any authority will issue a fatwa on their behalf. They follow the Hanafi school of jurisprudence, but the Hanafi guys issued a fatwa against the Taliban instead of for them.

https://en.wikipedia.org/wiki/Hanafi

That basically means they’re heretics.

These fundamentalist movements that have sprung up are doing so, largely, outside the context of what we might think of as the Catholic church. It’s like they’re ordaining their own priests, creating their own sacraments, and preaching their own heretical doctrines. This is like reform.

Meanwhile the umma has been struggling with modernity. Discovering the west both through media and travel has been huge. I think it’s a bit like the reformation happening at the same times as the scientific revolution. Some of the themes are the same, too.

I’ve sat in mosque and listened to people argue about whether western democracy is compatible with Islam. It was mostly younger Muslims who were born in the United States arguing with older Muslims who were born in the Middle East. Meanwhile, satellite television and the internet are having a huge effect on what people in North Africa and the Middle East are thinking about–much like the printing press did.

I see a lot of parallels.

And, anyway, I think the reforms we’re seeing are happening all over the Muslim world. Surely, Lutheranism and Calvinism were more fundamentalist than the Catholic church that preceded them. I see fundamentalist reforms like that and then backlashes against them happening everywhere from Turkey and Egypt to Tunisia and Libya. Let’s put the Calvinists in charge of Geneva! Let’s put the Muslim Brotherhood in charge of Egypt! At least we can trust the fundamentalists!

Turns out we can’t trust them either? Okay, well, then let’s ban their organization again!

Back and forth, back and forth . . .

Looks like reformation and counter-reformation to me.

What’s interesting is to read something like the “Al Qaeda Reader” by Raymond Ibrahim – it’s a variety of translated messages from Al Qaeda to various Islamic Groups/Organizations – generally very different in tone to the translated ones sent to the West….and generally not responded to at all positively in our context. He basically frames everything in strict literalist terms and they don’t have much to respond to in that context.

Similarly – “To Our Great Detriment” – I cannot recommend this highly enough in terms of context.